The Clock Jobber's Handybook

By Paul N. Hasluck

Brought to you by:

Tick Tock Productions ™

The

CLOCK JOBBER'S HANDYBOOK.

In putting the clock movement together, take especial care to see that the line is free, and on the right side of the pillars. When ready to adjust the line in its place, wind it upon the spring-barrel by turning the arbor ; and when the line is all wound upon the barrel, and the fusee pulled round as far as it will go, set up the main-spring one turn, and secure the click in the ratchet-wheel. Wind the clock up, carefully guiding, the line on the fusee, and see that the slopwork acts properly, and does not cut the line when it rubs. The snail on the fusee should catch against the stop directly the fusee grooves- are filled with the line. Foreign clocks have no fusee, the spring itself being wound round the barrel arbor on which he winding key is placed. The fusee is the distinguishing, characteristic in English spring dials.

French Clocks are of a style of

manufacture different altogether from the English, being distinguished

externally by their elaborate gilt, wood or stone cases, and internally by

finer mechanism, usually set between round plates, with short pendulum

rods and heavy bobs, in proportion to the length. There

are several varieties: timepieces, clocks which strike at the hour and at

the half-hour, carriage clocks, and drum timepieces of various kinds,

besides a large number of curious and fancy styles. They have movements

that are much more delicate and smaller than either English, American or

German clocks; in fact, they almost suggest a grade between clocks and

watches. The circular plates and the short and heavy pendulums usually

distinguish these clocks. Drum timepieces are perhaps the most familiar

specimens of French productions; they are a source of continual trouble to

the repairer. Being extremely portable, they are frequently carried about

the house, often on a tray; and, being very unstable, it is no unusual

occurrence, under such circumstances, to find that the drum timepiece is

rolled down a flight of stairs. The result may be more or less serious:

"a good shake" is the usual remedy. The better kinds of French

clocks give very accurate results, and the striking timepieces are so

delicate and fragile that amateurs should be very chary of them until some

manipulative skill has been acquired. With the exception of the drum

timepieces, French clocks, as a rule, perform uncommonly well, and give

the repairer very little trouble. Vienna regulators, or Austrian clocks,

are of later introduction, very much resemble French workmanship, and are

excellent time-keepers.

German Clocks are made chiefly of wood. Brass bushes are driven into the

wooden frames or plates, to form bearings for the pivots. Familiarly

called Dutch clocks, they are well known, being cheap, and fairly- good

time-keepers. Weights are the motive power, and they hang from the clock,

exposed together with the pendulum; this is a distinguishing feature. Most

German clocks may be easily known from those of any other nationality by

their plates of wood, with brass bushes for the pivots to run in; no other

country produces clocks made in this manner. The manufacture of clocks in

Germany is almost entirely confined to the locality of Black Forest, and

forms there an important branch of industry; nearly every form of ordinary

clock being made, in addition to large numbers of "cuckoo,"

"trumpeter," musical, automaton, and curious clocks. Hall Clocks

are the old-fashioned, long-cased clocks, standing six or seven feet high.

They have pendulums beating seconds, and have weights for the motive

power. When we look from the high standpoint of modern clockwork, in some

instances the workmanship of these old clocks is open to criticism. Still,

the whole machine is the best that has been designed for reliable

time-keeping. The solid construction of all its parts, and the regular

proportions of the wheels — so far as their numbers and revolutions are

concerned — and, above all, the seconds pendulum, and the long fall

given to the weights, combine qualities which, notwithstanding the rude

execution sometimes met with, give better results than any other class of

clocks made for household purposes. Regulators are constructed with every

possible care to ensure the greatest accuracy in time-keeping.

Astronomical observatories, watchmakers' shops, and occasionally the

houses -of private individuals who value extreme accuracy in time, are the

usual repositories for regulators. They generally have pendulums that beat

seconds, and which are compensated for variation in temperature. Mercurial

pendulums are now mostly used when cost is not a great object. Regulators

seldom require any other attention than cleaning very carefully and oiling

properly. On account of the value of the time-keeper and the delicacy of

the mechanism, the inexperienced jobber should not make any essays on

regulators. Skeleton Clocks are frequently found in common use. They are

made with pierced brass plates of ornamental design, and the entire

movement is exposed to view. A glass shade is placed over it to exclude

dust, &c. These clocks are very good time-keepers, and are interesting

inasmuch as they afford the opportunity of examining the mechanism when

going, and thus becoming familiar with its action. A simple eight-day

skeleton clock standing eighteen inches high made for about $25 with

marble stand and glass shade. The whole of the component parts, including

the frames, wheels, pinions, dial and hands may be bought. Amateurs having

a small lathe and a few other tools could fit the parts together: the

resulting clock being a reliable time-keeper and an ornament to the

mantel-shelf.

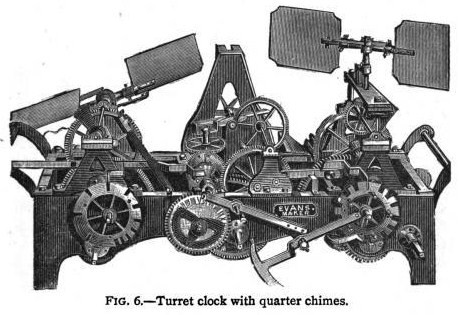

Turret Clocks are in construction similar to the ordinary kind, but the mechanism is much larger and stronger. They are placed in church towers, town halls and similar positions. In these large clocks the course of examining strictly enjoined as absolutely necessary in all house clocks may generally be dispensed with. The cause of stopping is usually apparent, and by trying the side-shake of the pivots in their holes, it can be readily felt if any new ones are required. The depths are nearly always correct, and the end-shakes can be tried the last thing when put together. The illustration, Fig. 6, shows a turret clock with the maker's name upon it. It chimes all the quarters, strikes hours on a ton bell, and shows time on four dials. It is constructed with the bed of cast-iron, 6 ft. long; all wheels and bushes are of gun-metal, the main wheels are 16 in. diameter and the teeth 1.5 in. wide, the pinions are cut from solid cast-steel, the escapement is Denison's double three-legged gravity. The pendulum compensation of iron and zinc tubes and steel rod, carrying a ball weighing two cwt. The quarters' cam barrel consists of iron rings, into which the cams for lifting the hammers fit, and can be adjusted in any way required. There are many recent improvements in the construction of this clock; all cams and levers are of cast-steel, hardened and tempered. Any wheel or pinion can be taken out of the frames separately, the bushes being screwed in at both ends ; there are over 900 pieces in the clock and dial work. There are two ways of treating church clocks : one consists FIG. 6. — Turret clock with quarter chimes.

of cleaning them as well as possible

with a brush, without removing any of the wheels from the frame, called

" wiping out; " and the other in taking them all to pieces and

thoroughly cleaning, in the same manner as small clocks. Which method is

necessary or desirable must be decided by judgment. It will be found

usually sufficient to thoroughly clean them about every five or six years,

and "wipe them out " once every year — about autumn being the

best time, before the cold weather sets in to influence the oil. When the

clock drives the hands at a distance, it is very necessary to see that the

leading-off rods and universal joints

Learn clock repair with these DVD courses! Course manuals are included.

Watch, study and learn antique clock repair through DVD course instruction using actual live repairs!!

Clock Repair 1 & 2 Advanced Clock Repair PRO advanced clock repair

Clockmaker Watchmaker Lathe Basics Clockmaker Watchmaker Lathe Projects Clock Case Repair & Restoration Wooden Works Movement Repair

© Copyright 2001-2009 by Tick Tock Productions © Copyright 2001-2009 by John Tope All rights reserved.

Back to clock information page.

Hasluck, Paul N. The Clock Jobber’s Handybook. London: Crosby Lockwood and Son, 1889.

This and the following pages are excerpts from the book.