The Clock Jobber's Handybook

By Paul N. Hasluck

Brought to you by:

Tick Tock Productions ™

The

CLOCK JOBBER'S HANDYBOOK.

PENDULUMS

THE CONTROLLERS.

CHAPTER V

EXAMINING AND CLEANING A 8-DAY CLOCK

Select

an ordinary eight-day English clock for our first lesson in clock jobbing,

because it is not easily injured, and is most likely to afford the largest

amount of information. We will assume that the clock only requires

examining and cleaning, and that no parts are missing or worn out.

When

the construction of this clock is thoroughly understood, no difficulty

will be found in repairing and adjusting other kinds; common errors,

peculiar to certain kinds, will be merely pointed out, and suggestions

made as to the treatment of the particular class under consideration.

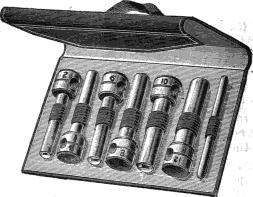

Sometimes the clock jobber is called upon to execute his work at some long distance from his workshop, and it may be advisable to take the necessary tools and complete the work at the clock owner's, using the kitchen table as his bench. The pocket case of tools shown at Fig. 17 is fitted up for such a purpose, and it also serves particularly for the work of an amateur who has not a fitted workshop.

The case, which is made of leather, contains, as may be

seen, a large screw-driver in the upper part, and in the lower part a

file, a pair of nippers or cutting pliers, a metal bottle for carrying

clock oil and fitted with an oiler, a pair of sliding tongs and a set of

six different-sized clock winders. These are of peculiar construction :

each key barrel has a round hole

diameter-ways across the head, and a steel rod, shown in the case, is

passed through this hole forming a cross T-shaped handle in the barrel

required to fit the clock to be wound. This form of clock-winding key is

particularly useful when case of carriage is the first consideration, and

deserves the attention of clock winders. Fig. 16 shows a pocket-case

containing a complete set.

Fig. 16. Case of Standard Clock Winders.

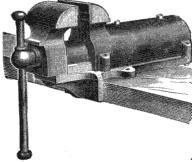

The work-bench used by the clock jobber should be sufficiently thick not to bend easily, and be well fixed, so as to be perfectly secure and steady. Towards that end which would be at the right hand when facing the board, a bench- vice must be secured for holding pieces to be filed, and other uses.

The bench-vice fixes to the bench by a clamp screw. The jaws are usually about from two to three inches wide. In the left-hand ends of the jaws there are always several indentations ; these are for taking the pointed end of the bow drill when drilling. The top of the claw is generally provided with a small surface for stake riveting and flattening drills, &c. Bench-vices frequently have jaws opening parallel, and are

.jpg)

Fig. 17. Pocket Case of Clock Jobbing Tools

.jpg)

Fig. 18. Bench-vice with Parallel Jaws and an Anvil.

fitted with small anvils, as shown at Fig. 18; some swivel round to any angle, and in many details are elaborated.

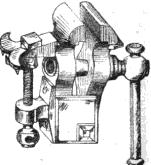

Fig. 19 shows a bench-vice which allows the movable jaw to be slid the whole extent of its travel, and grips any size between the jaws with half a turn of the handle.

As the jaws of bench-vices are usually of hard steel and have their gripping faces checkered, a pair of clams like Fig. 20 are often useful for holding work

Fig. 19. Quick Grip Parallel Bench-vice. likely to be injured by the steel jaws.

These clams are made of brass, and similar ones may be made of wood. Fig. 21 shows the ordinary bench-vice.

Fig. 19 shows a bench-vice.

Fig. 19 shows a bench-vice.

Fig. 20.

Clams for Bench-vice.

Fig. 20.

Clams for Bench-vice.

Fig. 21.

Ordinary Bench-vice

Fig. 21.

Ordinary Bench-vice

The tools required before commencing operations on this clock are one or two screw-drivers. A pair of strong pliers—some have jaws that close parallel as do those of one or two files, two or three brushes, a few taper strips of strong chamois leather and a card-brush made by fastening a pack of cards together.

Before taking the movement out of the case, it is often advisable to see whether any immediate cause of stopping can be found. The points to which attention should be directed are: The hands, to see if they are in any way bound; the catgut lines ; the striking parts, to see if there is any mishap connected with them ; and the pendulum, to see if it is free. If all these things are found correct, and the clock appears dirty, we may conclude that it wants cleaning at least, and that it may need some repairs which will necessitate its coming to pieces.

Being satisfied on these points, proceed to take off the two weights and the pendulum, and remove the movement to the work board to undergo the requisite examination, cleaning and repairs. Placing it, dial downwards, on the board, commence by taking out the screws by which the movement is fixed to the seat-board and removing this. The bell-stud screw is now unturned, and the bell, bell-stud, and screw placed on the board ; then the bridge or " cock " screws and the pallets taken out, and the cock screwed back in its place. The cock is replaced, so that the movement may be turned over without fear of scratching the back-plate, and it is left on till the last thing before the actual cleaning commences. The clock is now turned over face upwards, the small pin that secures the hands removed with the pliers, and the collet and the hands are taken off. In clock and watch work a " collet " very much resembles the washer or collar of other mechanical trades. Pull out the pins that hold the dial, and remove it.

Putting the movement on the board with the back-plate downwards, it will be well to take a good view of the mechanism, and acquire a knowledge of the names of the different parts, and something of their relative positions and uses.

The movement of a striking clock consists of two distinct sets of " trains " of wheels, set between two brass plates, which are kept the proper distance apart by turned pillars. These are riveted at one end into the back-plate, while the other ends pass through holes in the corners of the top-plate, and are there secured by pins. The proper way to tighten a pillar is to pin on the top-plate with the examining pins, rest the end of the pillar upon a hard wood block, and rivet it tight with a round-faced hammer. One train of wheels and pinions constitutes the going part of the machine, and the other, with the various appurtenances connected with it, the striking mechanism.

The going train comprises the first or great-wheel and barrel, upon which the line runs; the centre wheel and pinion; third wheel and pinion, and the escape wheel and pinion. The striking train comprises the striking great-wheel and barrel; pin-wheel and pinion; gathering-pallet-pinion and wheel; warning wheel and pinion; and the fly and its pinion. The names of the other parts of the clock are the pallets and crutch ; cock ; pendulum ; bell-stud and bell; motion-work, comprising the cannon-pinion, minute-wheel, hour^wheel and snail, the hammer and hammer-spring, lifter, detent, rack, rack-spring, and rack-hook. The parts of a clock-wheel are the teeth, the rim, the crossings or arms, and the collet, or brass hub on which the wheel is riveted. The parts of a pinion are the leaves or teeth, the arbor or axle, and the pivots which run in the holes.

_____________________________________________________________________________

Learn clock repair with these DVD courses! Course manuals are included.

Watch, study and learn antique clock repair through DVD course instruction using actual live repairs!!

Clock Repair 1 & 2 Advanced Clock Repair PRO advanced clock repair

Clockmaker Watchmaker Lathe Basics Clockmaker Watchmaker Lathe Projects Clock Case Repair & Restoration Wooden Works Movement Repair

© Copyright 2001-2009 by Tick Tock Productions © Copyright 2001-2009 by John Tope All rights reserved.

Back to clock information page.

Hasluck, Paul N. The Clock Jobber’s Handybook. London: Crosby Lockwood and Son, 1889.

This and the following pages are excerpts from the book.